JP INSTRUMENTS

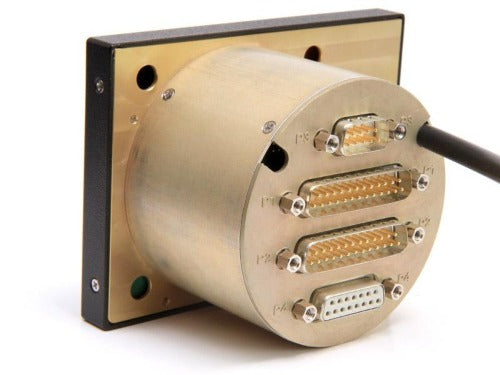

EDM-900 Engine Monitor

Part No: EDM-900-4CP-0

DESCRIPTION

EDM-900 Engine Monitor

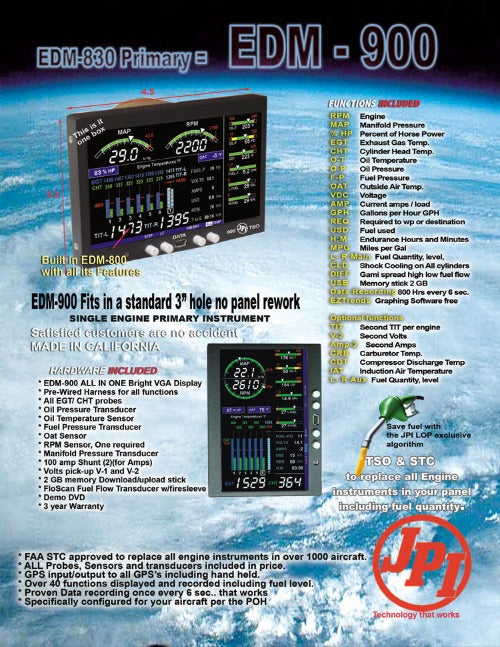

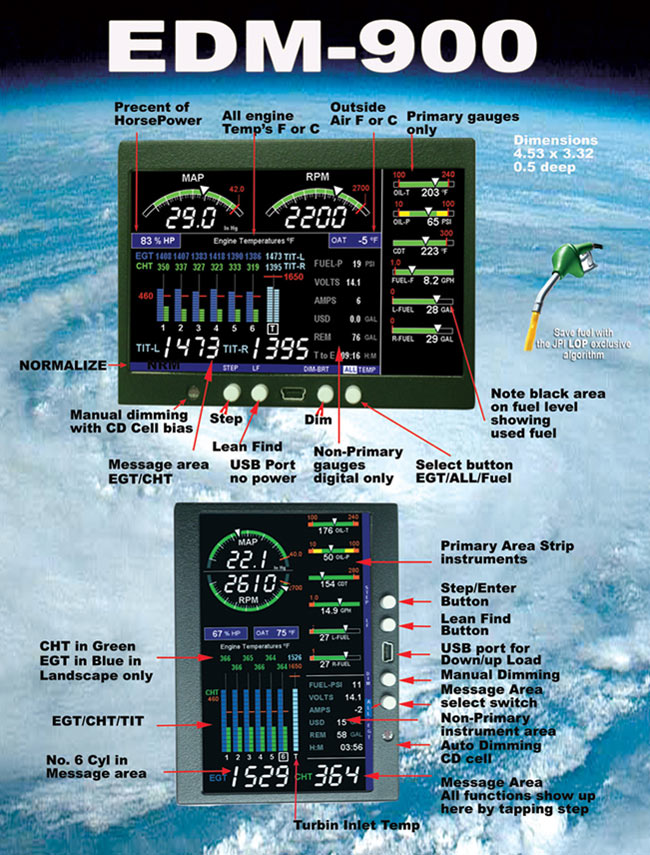

The EDM900 Primary system allows you to remove your old steam gauge instruments and move up to the most advanced and accurate piston engine-monitoring instrument on the market. Designed to be used both vertical or horizontally, the rear processor is offset to give almost unlimited install choices, and features a long list of user options. TSO’d as a PRIMARY instrument and for quality, the EDM 900 is not just another black box along for the ride. It is a Flight Engineer … a Maintenance Manager … a Backup Instrument. For the price there is nothing that gets close to it. You can almost think of the EDM 900 as your personal flight engineer. It’s always there, working in the background, constantly watching over your engine while you concentrate on flying the aircraft. You can make an entire flight without ever pushing a button, if you so choose. Yet your EDM will be monitoring your engine parameters three times a second and will warn you instantly if any parameter exceeds the programmed limit.

The new EDM-900 is certified as a replacement for existing analog engine gages including fuel quantity

(optional) and provides a full color engine display. The display fits in a standard 3 1/8” instrument hole

and the system includes all probes, sensors, and transducers for RPM, Manifold Pressure, EGT/CHT,

Oil Temp and Pressure, Fuel Pressure, Fuel Flow, OAT, and Volts/Amps. Standard JPI features include

data loading/memory, shock cooling warning, Lean Find, and percent horsepower. The EDM-900 is the

smallest certified engine monitor system available. Bezel size is 3.1” x 4” and it can display vertically

or horizontally.

Think of your EDM-930 Experimental as your personal flight engineer. Always there, working in the background, constantly watching over your engine while you concentrate on flying the aircraft. Your EDM-930 will be monitoring your engine conditions four times per second and will warn you instantly if any measurement exceeds the programmed limit.

Leaning is accomplished quickly and automatically using the LeanFind™ procedure. With the EDM it is now possible to have substantially more diagnostic information available to you in a timely and usable manner. The EDM 930 collects data and displays it for you in a useful way. You can use the EDM 930 to monitor engine temperatures and voltages, adjust the fuel/air mixture, and diagnose engine malfunctions.

Features

EDM-900 Systems Include Sensors and Probes for these Functions:

-

RPM

-

Manifold Pressure

-

Outside Air Temperature

-

Exhaust Gas Temperature (All Cylinders)

-

Cylinder Head Temperature (All Cylinders)

-

Oil Temperature

-

Oil Pressure

-

Fuel Pressure

-

Volts/Amps

-

Full Function Fuel Computer

-

2GB Memory Stick

-

Data Recording (800 hours every 6 Seconds)

-

Optional Functions Include:

-

Fuel Quantity (Up to Four Tanks)

-

Turbine Inlet Temperature

-

Carb Temperature

-

Induction Air Temperature

Specifications

• Pre-Wired Harness for all functions

• New Display SVGA & view angle 85 degrees all around

• Back lit buttons

• RPM Prop

• MAP Manifold Pressure

• % HP Percent of Horse Power

• EGT Exhaust Gas Temp.

• CHT Cylinder Head Temp.

• EGT Normalize mode

• LOP/ROP JPI Exclusive Leaning Mode

• O-T Oil Temperature

• O-P Oil Pressure

• F-P Fuel Pressure (when in POH)

• OAT Outside Air Temp.

• VDC Voltage (1)

• AMP Current amps (2 twins)

• Fuel Flow Transducer FlowScan

• GPH Gallons per Hour GPH

• REQ Required to wp or destination

• USD Fuel used

• H:M Endurance Hours and Minutes

• MPG Miles per Gal

• CLD Shock Cooling on ALL cylinders

• DIFF Difference between EGT’s

• USB Memory stick 1 GB

• Data Recording 800 Hrs every 6 sec.

• EZTrends Graphing Software free

• 3 year Warranty

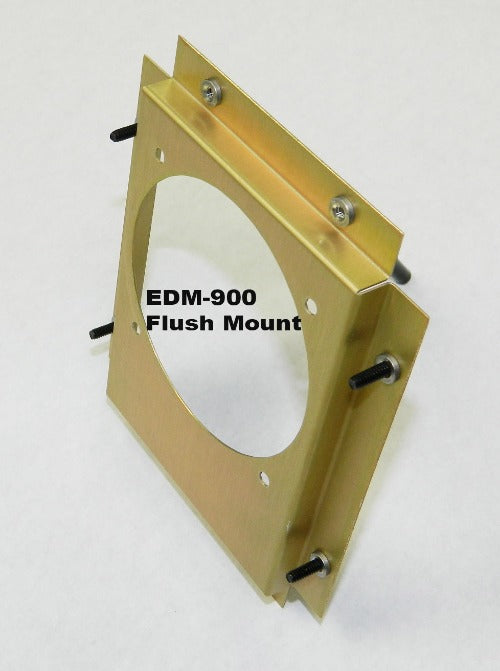

Dimensions: EDM-900 – 3.56″ deep (connectors recessed)- 4.81″ wide – 3.47″ high

Accuracy and Resolution, are two of the most misunderstood terms in instrumentation. Because an instrument displays 1 degree increments (resolution) does not mean it is accurate to 1 degree. JPI’s accuracy comes from its linearized thermocouples. Other’ put and estimating straight line through the center of the thermocouple calibration “S” curve. With this method the instrument is accurate at only three points along as the the straight line crosses the “S” curve. Therefore errors of +/- 10′ are quite possible while still displaying in 1degree resolution. Our competition is advertising +/- 1/2′ accuracy at full scale. This would mean that =/-1/2′ of 2000′ (full scale) is +/- 10′; there is a big difference. JPI has found nothing in the Aviation market that compares to our linearized accuracy.